Safety Tips for Faucet Repairs

Repairing faucets at home is a common task for homeowners and facility managers. Whether you’re dealing with minor drips, worn washers, or replacing old components, understanding how to handle faucet repairs safely is essential. This is especially important when working with plastic taps PVC systems, as their material characteristics differ from metal-based fixtures like brass or stainless steel. This article will guide you through common questions, valve definitions, applications, selection tips, installation precautions, and a comparison between brass and plastic valves—helping ensure a safer, smoother repair process.

Frequently Asked Questions (FAQ)

1. Are plastic taps PVC safe for home use?

Yes, high-quality PVC plastic taps are safe when manufactured according to international standards. They are widely used in residential plumbing systems for both cold and moderate hot water supply.

2. Can I repair plastic taps myself?

You can repair or replace basic components such as O-rings, cartridges, and washers in plastic taps. However, care must be taken not to overtighten or crack the fittings, as plastic is more brittle than metal.

3. What safety gear should I wear when repairing faucets?

Use gloves to protect your hands from sharp edges or hot water. Safety goggles are also recommended, especially when cutting or working with pressurized systems.

4. What’s the difference between PVC and CPVC taps?

PVC is mainly used for cold water systems, while CPVC has higher temperature resistance and can handle hot water applications. Make sure to use the right type for your specific needs.

5. How long do plastic taps typically last?

Plastic taps made from quality PVC can last 5–10 years, depending on water quality, usage frequency, and environmental exposure.

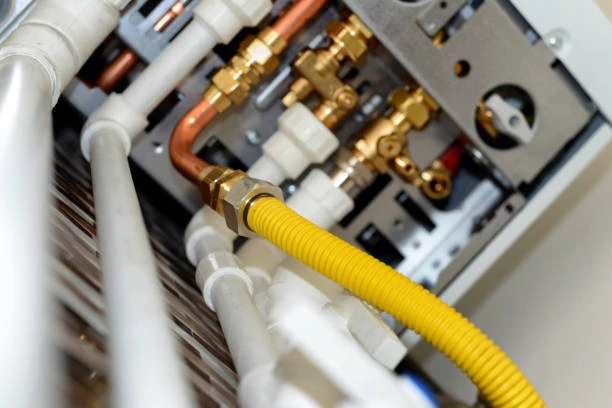

Brass Valve Basics: Definition and Features

A brass valve is a mechanical control device made from a copper-zinc alloy. It is commonly used in water distribution systems to start, stop, or regulate water flow. Unlike plastic valves, brass offers long-term durability and structural strength.

Main Features of Brass Valves:

Durability: Brass can withstand high pressures and harsh environments.

Corrosion Resistance: It performs well in both acidic and alkaline conditions.

Temperature Tolerance: Suitable for both hot and cold water lines.

Reliability: Less prone to cracking or deformation over time.

Precision Engineering: Brass valves typically offer tighter seals and smoother operation.

These characteristics make brass valves ideal for applications requiring strength and longevity.

Common Applications and Industries

Plastic taps PVC and brass valves serve many overlapping, yet distinct, use cases across residential, commercial, and industrial fields.

PVC Plastic Taps:

Residential Bathrooms & Kitchens: Lightweight and budget-friendly, ideal for sinks and laundry rooms.

Gardening & Outdoor Use: PVC taps are resistant to rust and work well in outdoor settings.

Temporary or Mobile Installations: Perfect for caravans, mobile homes, and portable systems.

Chemical Laboratories: Some PVC variants can handle light chemical usage.

Brass Valves:

Municipal Water Systems: Used where long-term durability is required.

Industrial Water Control: Preferred in factories and mechanical systems.

High-Pressure Zones: Ideal for fire suppression and commercial plumbing.

By understanding the application needs, users can better select materials suited for specific environments.

Buying Guide: How to Choose the Right Tap

When selecting a faucet—whether metal or plastic taps PVC—it’s important to review several key specifications to ensure the product fits your needs.

1. Material Type

PVC (Polyvinyl Chloride): Lightweight, corrosion-resistant, and inexpensive.

CPVC (Chlorinated PVC): Better for hot water systems.

Brass: Heavy-duty, corrosion-resistant, and long-lasting.

2. Design & Finish

Plastic taps come in various colors (white, black, grey) and styles. Choose one that complements your bathroom or kitchen interior.

3. Water Pressure Rating

Check the product’s maximum water pressure capacity. Most PVC taps are suitable for low to moderate pressure systems.

4. Certifications

Look for compliance with ISO, NSF, or CE standards. Certified products meet strict safety and quality requirements.

5. Ease of Maintenance

Choose taps with accessible parts and standard sizes to make repairs easier in the future.

By taking time to review these factors, you reduce the risk of future leaks, replacements, or malfunctions.

Installation Tips

Proper installation is just as important as quality materials. Here are some tips for safely installing plastic PVC taps:

Pre-Installation:

Shut off the main water supply to avoid accidents.

Check that all parts and accessories are included.

Prepare tools such as an adjustable wrench, sealing tape, and a level.

During Installation:

Do not overtighten PVC components, as this can cause stress fractures.

Use PTFE (Teflon) tape on threaded connections to prevent leaks.

Avoid mixing metal and plastic threads directly to prevent damage.

Post-Installation:

Turn water back on slowly while observing the tap for leaks.

Test the tap under full pressure to confirm correct installation.

Check alignment to ensure aesthetic and functional accuracy.

If you’re unsure about any step, it’s advisable to consult a plumber.

Brass Valves vs. Plastic Valves: Comparison Table

| Feature | Brass Valve | Plastic Valve (PVC) |

|---|---|---|

| Strength | High mechanical strength | Lower strength, more brittle |

| Corrosion Resistance | Excellent | Very good (non-metallic) |

| Heat Resistance | High – good for hot water | Moderate – not ideal for high heat |

| Longevity | 10–20 years or more | 5–10 years |

| Installation Ease | Requires tools and fittings | Easier to cut and install |

| Weight | Heavier | Lightweight |

| Cost | More expensive upfront | More budget-friendly |

| Recyclability | Easily recyclable | Some types recyclable |

| Typical Use | Permanent installations | Temporary or light-use setups |

While plastic taps are ideal for lightweight and affordable applications, brass valves are better suited for demanding and high-pressure systems.

Conclusion

Safety and efficiency go hand in hand when repairing or installing faucets. Whether you’re working with plastic taps PVC or durable brass valves, understanding the material, application, and correct installation methods ensures fewer issues and a longer service life. Always wear proper protective equipment, follow manufacturer guidelines, and choose certified products. By doing so, you’ll reduce water waste, prevent accidents, and enjoy reliable plumbing for years to come.

Connect

IFAN is a trusted Chinese manufacturer specializing in plastic pipes, fittings, and valves, with over 30 years of industry experience. We offer a wide range of plastic taps PVC, copper valves, and piping system components that meet global standards.

If you’re interested in purchasing durable, cost-effective, and certified valve products, we’re here to help.

- For more information,pls visit our webside https://waterpipefitting.com/

Pls Mailto: [email protected]

Whatsapp: +86 15088288323

We respond to emails and faxes within 24 hours. For urgent matters, feel free to call us directly. We’re committed to quality and customer satisfaction.

IFAN Products International Standards

All IFAN products comply with a wide range of global standards, ensuring performance, safety, and compatibility:

ISO 15874, EN 15874, ASTM F2389, DIN 8077/8078, GB/T 18742, NBR 15884, ISO 15494, EN ISO 15494, GB/T 19472, NBR 15494, ASTM 2846 (501), DIN 8079/8080 (502), ASTM F441/F441M SCH80 (503), DIN (504), DIN (505), GB/T 18993, AS/NZS 1477, CSA B137.6, NSF/ANSI 14, TIS 17-2532/1131-2535, BS 3505, BS 4346 (801), ASTM D1785 SCH40 (802), ASTM D1785 SCH80 (803), DIN (804), GB (805), GB (806), GB(901), DWV(902), ASTM D2665 (903), ASTM D2241, D2729, F441/F441M, ISO 1452, EN ISO 1452, DIN 8061/8062, GB/T 10002, AS/NZS 1477, JIS K6741, CSA B137.3, and more.

Recent Comments