Introduction to PPR Piping

PPR (Polypropylene Random Copolymer) piping has gained popularity in various industries. This material offers numerous advantages, such as corrosion resistance and low thermal conductivity. soudeuse ppr are widely used in plumbing, heating, and cooling systems. Their lightweight nature simplifies installation and reduces transportation costs. The industry is witnessing a shift towards using PPR piping due to its long lifespan and sustainability.

Sustainability and Environmental Impact

Sustainability remains a crucial concern in today’s world. PPR piping contributes to environmental protection in various ways. First, it has a lower carbon footprint compared to traditional materials. Moreover, PPR is fully recyclable. This characteristic enhances its appeal to environmentally conscious consumers. Manufacturers are now focusing on producing eco-friendly soudeuse ppr. For example, they utilize recycled materials in their production processes. This trend indicates a growing awareness of environmental issues in the piping industry.

Technological Advancements

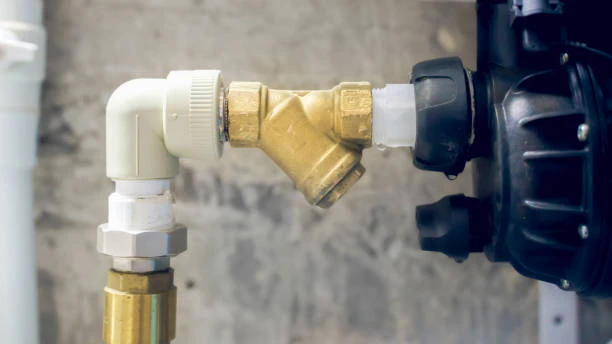

Technology continues to evolve, shaping the future of PPR piping. Innovations in manufacturing processes enhance the quality of PPR pipes. The introduction of automated systems improves efficiency and reduces costs. Advanced techniques, such as fusion welding, ensure stronger joints. These advancements lead to longer-lasting systems and reduced maintenance needs. Additionally, smart technology integration allows for better monitoring of piping systems. These features contribute to the overall efficiency of PPR piping systems.

Market Growth and Demand

The demand for PPR piping is on the rise globally. Several factors drive this growth. First, urbanization increases the need for reliable plumbing systems. Additionally, industries such as construction and agriculture boost PPR pipe usage. The shift towards green building practices also promotes PPR’s popularity. For instance, many architects and engineers now specify PPR pipes in their projects. This trend reflects a broader movement towards sustainable construction materials.

Applications in Various Industries

PPR piping finds applications across numerous sectors. In residential construction, it serves as an efficient plumbing solution. In industrial settings, PPR pipes transport chemicals and other fluids. The agricultural sector uses PPR for irrigation systems. Each application benefits from PPR’s durability and resistance to various substances. For example, PPR pipes can withstand high temperatures and pressures. This versatility makes PPR a preferred choice in many industries.

Competitive Landscape

The PPR piping market features several key players. Leading manufacturers focus on innovation and quality. They strive to differentiate their products in a crowded market. Companies invest in research and development to create superior PPR piping solutions. Moreover, they emphasize customer service and support. This focus on quality and service fosters brand loyalty among consumers. As competition intensifies, companies must adapt to market trends and demands.

Challenges in the Industry

Despite the growth, the PPR piping industry faces challenges. One significant issue is the fluctuation of raw material prices. This variability can impact production costs and pricing strategies. Additionally, competition from alternative materials poses a threat. For instance, PVC piping remains a strong contender in the market. Companies must address these challenges to maintain their market positions. Strategic planning and innovation are essential for staying ahead in the industry.

Conclusion and Future Outlook

The future of PPR piping remains bright, driven by various trends. Sustainability and technological advancements will shape its trajectory. Increased demand across multiple industries will further fuel growth. Companies must remain agile to adapt to changing market conditions. By focusing on innovation and quality, manufacturers can ensure long-term success. As the industry evolves, PPR piping will continue to play a significant role in modern infrastructure. The focus on solutions like soudeuse PPR will enhance installation efficiency and reliability, further solidifying PPR’s position in the market.

IFAN Products international standards

IFAN products strictly adhere to a comprehensive range of international standards, encompassing ISO 15874, EN 15874, ASTM F2389, DIN 8077/8078, GB/T 18742, NBR 15884, ISO 15494, EN ISO 15494, GB/T 19472, NBR 15494, ASTM 2846 (501), DIN 8079/8080 (502), ASTM F441/F441M SCH80 (503), DIN (504), DIN (505), GB/T 18993, AS/NZS 1477, CSA B137.6, NSF/ANSI 14, TIS 17-2532/1131-2535, BS 3505, BS 4346 (801), ASTM D1785 SCH40 (802), ASTM D1785 SCH80 (803), DIN (804), GB (805), GB (806), GB(901), DWV(902), ASTM D2665 (903), along with ASTM D2241, D2665, D2729, and F441/F441M series, ISO 1452, EN ISO 1452, DIN 8061/8062, GB/T 10002, AS/NZS 1477, JIS K6741, CSA B137.3, and other national and industry norms.

Connect

IFAN is a Chinese manufacturer of plastic pipes, fittings and valves with 30 years of experience. If you are interest in IFAN copper fittings, copper valves, plastic pipes and fittings, please contact us. IFAN offers you a variety of standard pipes to meet your specific needs. Click below to learn more about IFAN’s wide range of affordable and cost-effective valve products and piping system related products.

We will reply your email or fax within 24 hours.

You can call us at any time if there is any question on our production.

For more information,pls visit our webside https://waterpipefitting.com/

Pls Mailto: [email protected]

Whatsapp: +86 15088288323

Recent Comments