Handling Common Issues in Faucet Repairs

When it comes to bathroom and kitchen maintenance, the modern design basin water mixer tap is a popular and practical choice that combines functionality with sleek aesthetics. However, like all fixtures, taps can develop issues over time. From minor leaks to poor water pressure, these problems often stem from wear, incorrect installation, or substandard components. Understanding how to diagnose and resolve these issues can save time and money, while maintaining the long-term performance and visual appeal of your tap system.

This article will help you troubleshoot common tap faults, explain the function and benefits of brass valves, and provide an in-depth guide on how to choose and install taps effectively. We’ll also compare brass and plastic valves and share expert advice to ensure you make informed plumbing decisions.

Frequently Asked Questions (FAQ)

1. Why is my modern design basin water mixer tap leaking?

Leaks often occur due to worn-out internal washers or damaged ceramic cartridges. In some cases, incorrect installation or mineral build-up inside the valve can also lead to drips or inconsistent water flow.

2. How do I fix low water pressure in a mixer tap?

Check the aerator for blockages. If that doesn’t help, examine the inlet hoses or the cartridge for scale. Cleaning or replacing these parts usually resolves the problem.

3. Can I repair a mixer tap myself?

Yes, most common issues like replacing cartridges or aerators can be done as a DIY job. However, for internal damage or pipe-related issues, professional help is advised.

4. What does the check valve do in a mixer tap?

A check valve prevents water from flowing back into the main supply, which protects your water system from contamination and maintains balanced water pressure.

5. How long should a modern basin mixer tap last?

A quality modern design basin water mixer tap, particularly one made from brass, can last 10–15 years or more with proper maintenance.

Brass Valves: Definition and Key Characteristics

Brass valves play a crucial role in plumbing systems, especially in controlling water flow and ensuring leak-proof connections. A brass valve is a control mechanism made from a copper-zinc alloy, which is highly durable and corrosion-resistant.

Key Features of Brass Valves:

High Strength: Withstands high pressure and temperature fluctuations.

Excellent Corrosion Resistance: Ideal for both cold and hot water applications.

Long Service Life: Brass valves outlast most plastic counterparts.

Non-toxic and Safe: Brass inhibits bacterial growth, ensuring hygienic water.

Versatile: Suitable for residential, commercial, and industrial systems.

Brass is particularly beneficial in modern design basin water mixer taps, where appearance and durability are both important.

Common Applications of Brass Valves and Mixer Taps

Brass valves and mixer taps are extensively used due to their reliability, aesthetic appeal, and compatibility with various plumbing systems.

Residential Use:

Bathroom sinks and basin mixer taps

Kitchen sink mixer faucets

Garden and laundry taps

Commercial and Hospitality Industry:

Hotel bathrooms and washbasins

Restaurant kitchen taps

Public restrooms in shopping centres

Industrial and Healthcare Settings:

Cleanroom laboratories

Hospitals and dental clinics

Manufacturing plants using controlled water systems

Mixer taps, especially those with a modern design, are chosen for their ability to regulate temperature and flow through a single control lever.

Buying Guide: Choosing a Modern Design Basin Water Mixer Tap

Selecting the right mixer tap ensures efficient water usage, comfort, and long-lasting performance. Here’s what to consider:

1. Material

Choose taps made from solid brass for durability and corrosion resistance. Avoid low-grade alloys or plastic-bodied taps which may fail prematurely.

2. Valve Mechanism

Look for ceramic disc cartridges, which are smoother and longer-lasting than rubber washers. Also, ensure there’s an integrated check valve to prevent backflow.

3. Finish and Design

Match the tap finish (chrome, matte black, brushed nickel) with your basin and décor. The modern design basin water mixer tap should be both functional and visually aligned with your bathroom aesthetics.

4. Water Pressure Compatibility

Check whether the tap is suitable for your water system—some taps require a minimum pressure level to function properly.

5. Certifications

Ensure the product meets international standards like ISO, EN, or NSF, confirming the product’s safety and performance in water systems.

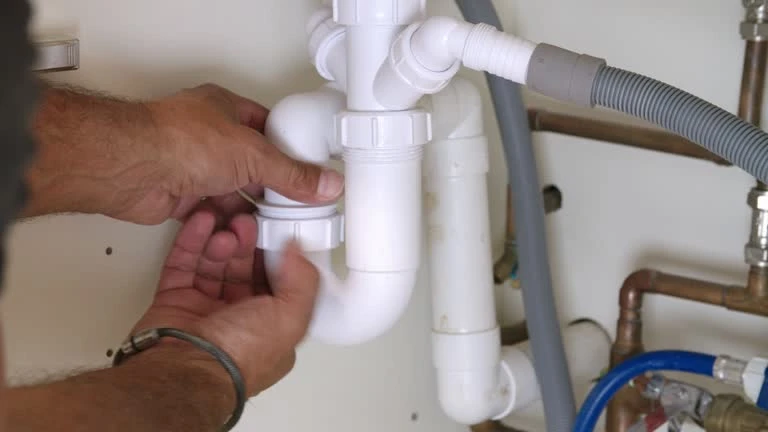

Installation Tips for Modern Mixer Taps

Correct installation is vital to avoid common issues such as leaks, noise, or low pressure. Below are practical steps for installing a modern design basin water mixer tap:

Step-by-Step Guide:

Turn Off the Water Supply: Shut off the main or local valve before starting.

Position the Tap: Insert the tap into the basin hole, aligning it correctly.

Secure the Tap: Tighten mounting nuts and washers underneath the basin.

Connect the Flexi Hoses: Use PTFE tape on threads and connect the hot and cold water feeds to the correct inlets.

Test for Leaks: Turn on the water and observe for any leakage. Tighten if needed.

Allow a few hours to observe performance after installation, particularly if new valves were used.

Brass Valves vs Plastic Valves: A Practical Comparison

Understanding the differences between brass and plastic valves can help in choosing the right components for your plumbing system.

| Feature | Brass Valves | Plastic Valves |

|---|---|---|

| Durability | Excellent, supports high pressure and impact | Moderate, susceptible to wear over time |

| Temperature Resistance | Performs well under hot/cold conditions | May soften or warp under high temperatures |

| Corrosion Resistance | Naturally corrosion-resistant | May degrade under UV or chemical exposure |

| Hygiene | Antimicrobial surface, safe for potable water | May support bacteria if not maintained |

| Weight and Handling | Heavier, requires secure mounting | Lightweight and easier to install |

| Environmental Impact | Recyclable, long lifecycle | Limited recyclability, shorter lifespan |

| Cost | Higher initial cost, better value long-term | Lower upfront cost but needs more frequent replacement |

Overall, brass valves offer more reliability and are the preferred option for modern basin taps and high-traffic plumbing environments.

Conclusion

Dealing with issues in mixer taps doesn’t need to be stressful. By understanding the common causes—such as worn parts, scale build-up, or improper installation—you can resolve most problems with simple maintenance. The modern design basin water mixer tap is an essential fixture in many homes and businesses, combining aesthetics with functionality.

Choosing quality brass components, performing regular checks, and following proper installation practices all contribute to a longer-lasting and more reliable tap system. While plastic valves offer some cost savings, brass remains the superior option for durability, hygiene, and performance.

Connect

IFAN is a leading Chinese manufacturer with over 30 years of experience in producing high-quality plastic pipes, brass fittings, and valves. We offer a broad selection of brass water mixer taps, bib check taps, copper fittings, and other plumbing components that comply with strict international standards.

Whether you are working on residential renovations or large commercial installations, IFAN has a solution tailored to your needs.

Contact IFAN:

- For more information,pls visit our webside https://waterpipefitting.com/

Pls Mailto: [email protected]

Whatsapp: +86 15088288323

Our team is available to answer all your product enquiries. We guarantee a response within 24 hours via email or fax, and we welcome calls for immediate support.

IFAN Product International Standards

All IFAN plumbing products meet global industry requirements. Our offerings are certified and manufactured according to the following standards:

International Standards Include:

ISO 15874, EN 15874, ASTM F2389, DIN 8077/8078, GB/T 18742, NBR 15884, ISO 15494, EN ISO 15494, GB/T 19472, NBR 15494, ASTM 2846 (501), DIN 8079/8080 (502), ASTM F441/F441M SCH80 (503), DIN (504), DIN (505), GB/T 18993, AS/NZS 1477, CSA B137.6, NSF/ANSI 14, TIS 17-2532/1131-2535, BS 3505, BS 4346 (801), ASTM D1785 SCH40 (802), ASTM D1785 SCH80 (803), DIN (804), GB (805), GB (806), GB(901), DWV(902), ASTM D2665 (903), along with ASTM D2241, D2665, D2729, and F441/F441M series, ISO 1452, EN ISO 1452, DIN 8061/8062, GB/T 10002, AS/NZS 1477, JIS K6741, CSA B137.3, and other regional plumbing norms.

These standards ensure performance, safety, and compatibility across international projects.

Recent Comments