List of Faucet Repair Materials

When a faucet starts leaking or functioning poorly, having the right repair materials makes all the difference. This is especially true for a water boiler tap, which handles both temperature-sensitive and high-pressure conditions. Repairing or maintaining these taps requires a good understanding of their internal components, materials, and installation requirements. In this article, you’ll find a complete list of faucet repair materials, explore the characteristics of brass valves, review installation tips, and compare brass and plastic valves for different use cases. Whether you’re handling routine maintenance or replacing worn parts, this guide will help ensure long-lasting faucet performance.

Frequently Asked Questions (FAQ)

1. What tools and parts are typically needed for repairing a water boiler tap?

You may need replacement washers, O-rings, valve cartridges, Teflon tape, pliers, and an adjustable wrench. For boiler taps, heat-resistant parts are also important.

2. How can I identify the cause of a faucet leak?

Leaking often results from a worn washer, faulty valve seat, or deteriorated O-ring. Noise or stiffness may point to scale buildup or a damaged cartridge.

3. Can I repair a water boiler tap myself?

Yes, many basic repairs are DIY-friendly if you have the right tools and follow safety steps. However, taps connected to boilers should be handled carefully due to heat and pressure.

4. How often should a faucet be inspected or maintained?

Check every 6 to 12 months for signs of leaks, corrosion, or reduced water pressure, especially in hard water areas.

5. What’s the difference between a standard tap and a water boiler tap?

A water boiler tap is designed to handle high temperatures and deliver near-boiling water instantly. It requires heat-resistant components and stricter material standards.

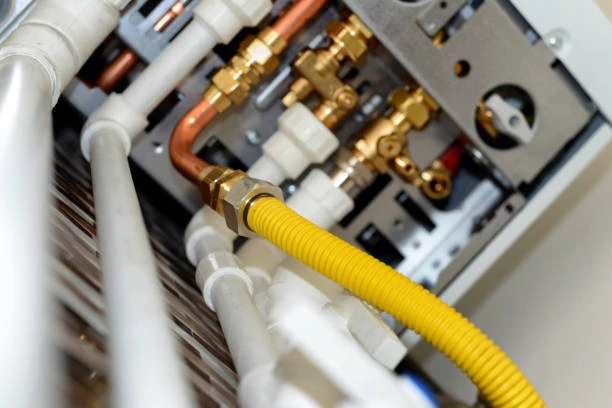

Brass Valves: Definition and Key Features

Brass valves are widely used in water boiler taps due to their excellent performance and resistance to corrosion. A brass valve consists of an alloy made from copper and zinc, making it both strong and long-lasting. These valves perform well in high-pressure and high-temperature settings, which is crucial in a boiler tap environment.

Key features of brass valves include:

Durability: Withstand long-term wear and thermal expansion.

Corrosion Resistance: Ideal for hot water use, resisting oxidation and scaling.

Malleability: Easily shaped into precise components for better water control.

Thermal Stability: Perform well under fluctuating temperatures without warping.

Lead-Free Options: Available in drinking-water-safe variants with low lead content.

These properties make brass the go-to choice for industrial, residential, and commercial water boiler tap systems.

Applications and Industry Use Cases

Water boiler taps and brass valves are used in a wide range of applications across different industries:

Residential Kitchens: Used for instant hot water delivery in tea stations or under-sink water heaters.

Hospitality and Restaurants: Enable rapid hot water access for cooking, cleaning, and drink preparation.

Healthcare and Labs: Ensure safe, sterile hot water availability where hygiene is critical.

Schools and Offices: Provide convenience and efficiency in high-use environments.

Manufacturing Facilities: Integrated in hot water systems or boilers for industrial processing.

Thanks to their reliability and heat resistance, brass valves and boiler taps are essential components in demanding environments.

Buying Guide: What to Look for in Faucet Repair Materials

When purchasing faucet repair materials for water boiler taps, consider the following:

1. Material Quality

Always choose heat-resistant components, especially washers, seals, and valve bodies. Brass is preferred for valves, while silicone or Viton is ideal for gaskets.

2. Compatibility

Match the parts with your existing tap model. Not all cartridges and valve stems are universal.

3. Certification

Look for products certified for high-temperature and potable water use. Standards like NSF, WRAS, or ISO indicate safety and quality compliance.

4. Finish and Design

If you are replacing the visible parts (like handles or spouts), ensure the finish matches the existing fixture—stainless steel, chrome, or matte black are common options.

5. Ease of Installation

Some parts, like push-fit cartridges or pre-lubricated O-rings, make installation easier and reduce the risk of leaks.

Installation Tips for Water Boiler Taps

Installing or repairing a water boiler tap involves more than just attaching parts. Here are important tips:

Turn Off Water and Power: Shut off the water supply and disconnect any heating source before starting work.

Use Teflon Tape: Always wrap threaded connections to prevent leaks, especially under pressure.

Tighten Carefully: Over-tightening can damage seals or crack plastic components. Use moderate pressure with the correct tools.

Check for Leaks: After installation, run the tap and inspect all joints under both hot and cold water flow.

Use Heat-Resistant Components: Never install regular rubber washers in a boiler tap. Use only components rated for high heat.

Following these steps ensures a safe and long-lasting repair.

Brass Valve vs. Plastic Valve: A Direct Comparison

| Feature | Brass Valve | Plastic Valve |

|---|---|---|

| Material Strength | High; resists cracking and distortion | Moderate; weaker under high pressure |

| Temperature Tolerance | Excellent for hot water and boiler taps | Limited; may deform with heat |

| Corrosion Resistance | Strong; long-term protection | Good; depends on water and environment |

| Safety for Drinking Water | Safe if lead-free certified | Safe if food-grade certified |

| Cost | Higher upfront cost | More affordable |

| Environmental Impact | Recyclable and long-lasting | Less durable; may require frequent replacement |

| Typical Usage | Boilers, kitchens, industrial systems | Garden taps, low-pressure indoor use |

For any high-temperature or pressure system like a water boiler tap, brass valves are the safer and more reliable choice.

Conclusion

Having the right faucet repair materials on hand ensures your water boiler tap operates smoothly and safely. Understanding the importance of components such as brass valves, O-rings, and valve cartridges can save you time and cost during maintenance. Whether you’re a DIY enthusiast or managing a commercial system, investing in certified, heat-resistant materials will prevent leaks and extend the life of your fixtures. Be sure to follow installation best practices, compare materials wisely, and select parts designed for your specific tap system.

Connect

IFAN is a trusted Chinese manufacturer with over 30 years of experience in plastic pipes, fittings, and valve production. If you’re looking for reliable brass fittings, copper valves, or plastic piping components, IFAN is here to help. We offer a wide range of standard and custom products to meet your plumbing needs.

- For more information,pls visit our webside https://waterpipefitting.com/

Pls Mailto: [email protected]

Whatsapp: +86 15088288323

You’ll receive a response to your email or fax within 24 hours. For urgent inquiries, feel free to call us anytime. We’re committed to providing fast, friendly service and dependable solutions.

IFAN Products and International Standards

IFAN products comply with an extensive list of global standards, including:

ISO 15874, EN 15874, ASTM F2389, DIN 8077/8078, GB/T 18742, NBR 15884, ISO 15494, EN ISO 15494, GB/T 19472, NBR 15494, ASTM 2846, DIN 8079/8080, ASTM F441/F441M SCH80, AS/NZS 1477, CSA B137.6, NSF/ANSI 14, TIS 17-2532/1131-2535, BS 3505, BS 4346, ASTM D1785 SCH40, ASTM D1785 SCH80, GB(901), DWV(902), ASTM D2665 (903), ISO 1452, EN ISO 1452, DIN 8061/8062, GB/T 10002, JIS K6741, CSA B137.3, and more.

These standards ensure IFAN’s product quality, performance, and compatibility across global markets.

Recent Comments