Products

Showing 37–48 of 70 results

Ifan Advanced plumbing systems

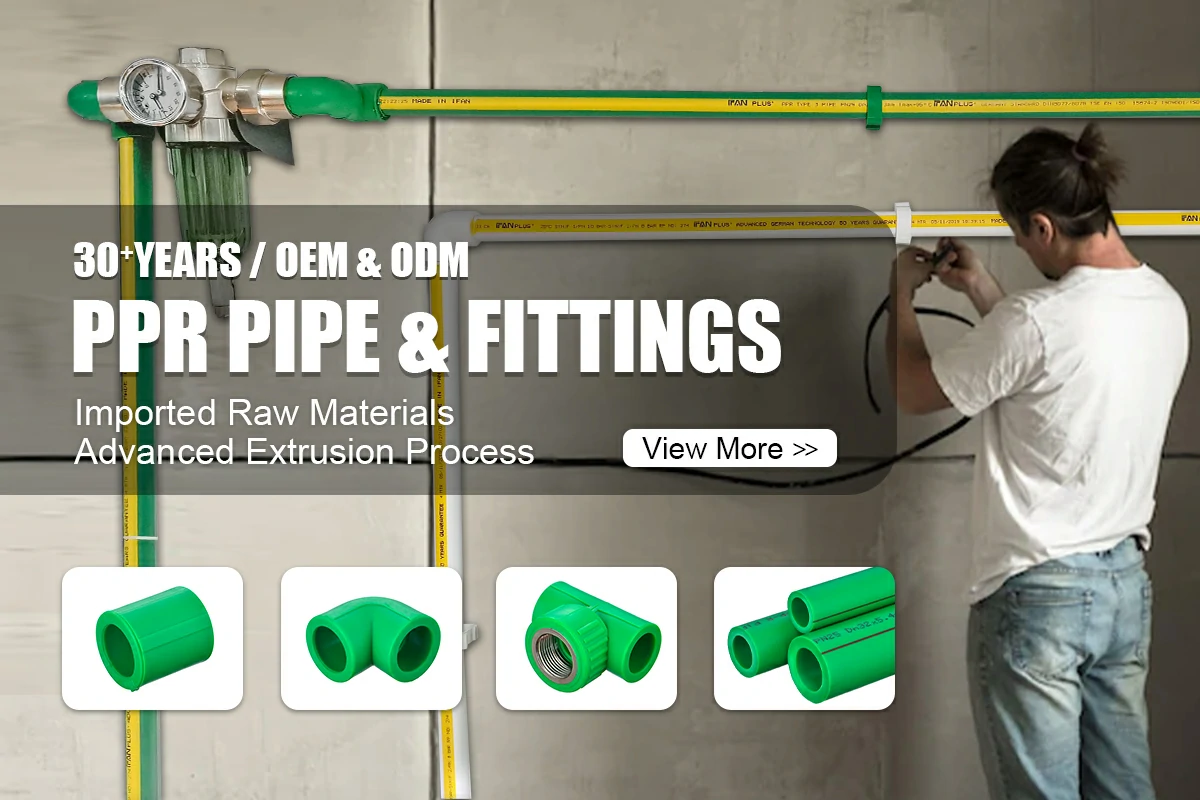

Our factory boasts strong capabilities with nearly 30 years of history and a robust financial chain, focusing on producing high-quality plumbing materials. We have our own mold factory with complete molds that adapt to different national standards.

We have a professional team that covers all aspects, including design, production, sales, technology, quality inspection, transportation, logistics, and order tracking. We offer OEM customization services to meet various customer needs, especially in the plumbing materials sector.

We maintain long-term stable partnerships with globally renowned raw material suppliers, ensuring we can provide high-quality products like supply ppr and Wholesale plastic pipes.

Our factory has its own export capabilities and maintains a safe inventory, ensuring timely delivery, which showcases significant advantages, particularly in collaboration with pipe manufacturers.

Equipped with fully automated machinery, our factory achieves high production efficiency, standardized production, quick delivery times, a wide variety of products, and competitive prices, especially in bulk ppr and mass ppr supplies.

We have a high-spec laboratory that meets both internal and customer inspection and testing requirements, ensuring that every batch of plumbing materials meets the standards.

Our advantageous location facilitates cooperation with Yiwu Trade City, attracting many overseas partners. Additionally, we are close to the ports of Hangzhou and Ningbo, making sea transportation convenient. We welcome you to visit our factory in China to learn more about our plumbing materials and trade ppr advantages!

IFAN FACTORY ORIGINATED IN 1993.

As an expert in pipes, providing high-quality products and excellent customer service is crucial to our business

Production of PPR

PPR Pipes

A PPR pipe is a straight and stiff cylindrical pipe made of Polypropylene Random Copolymer Plastic PPR Pipe Fitting that is extruded continuously. They are frequently available in green or white, with outside diameters spanning from 20mm to 110mm, resulting in pipe walls that are significantly thicker than PVC.

Chemically purer and robust, PPR pipes are less likely to crack under pressure or corrode and thus deter leaking. With a smooth inner surface, our PPR pipes can carry drinking water cleanly, not leaving any color, odor, or unusual taste and preserving its quality for circulation throughout the piping system. Along with corrosion and chemical resistance, our PPR pipes are suitable at freezing and scorching temperatures, making them work in various environments.

- Lightweight: Because of their modest weight, our PPR pipes significantly cut shipping costs and installation complexity.

- Uses green building components that are hygienic and non-toxic: Our entire raw material synthesis, manufacturing processing, product usage, and disposal process has no negative consequences on the human body or the environment.

- Heat preservation and heat resistance: We fully fulfill the requirements of the hot water system stipulated in the building water supply and drainage design code.

- Good corrosion resistance: With the exception of a few oxidants, they endure the erosion of a wide range of chemical media, will not rust, corrode, or produce germs.

Water flow resistance is minimal: Our PPR pipe’s inner wall is smooth, will not scale, and has a wear resistance system.

Aluminum PPR Pipes

This pipe consists of three layers: the pipe and the coat are make of PP-R with aluminium foil in between. The Aluminium foil is attached with. wrapping welding and by using a special PP coating film to establish the mechanical connection between the aluminium foil and the PP-R layer.

1. Low thermal expansion

2. Oxygen impermeability

3. Low heat loss

4. High resistance to pressure and heat

5. Easy forming, installation and application

6. Hygenic

7. Resistance to chemicals

8. Low pressure loss due to the smoothness

1. All kinds of hot and cold water installations

2. Air pressure installations.

3. Heating installations and radiator connections.

4. Industry.

PPR Pipe Fittings

- PPR pipe fittings, is a kind of ppr as raw materials, processed pipe fittings.

- PPR is random copolymer polypropylene, also known as type three polypropylene.

1)non-toxic, hygienic.

2)Heat preservation and energy saving.

3)better heat resistance.

4)long service life, up to 50 years.

5)easy installation, reliable connection.

6)the material can be recycled.

1)PPR Hot Water Pipe is Cold and hot water systems of buildings, including central heating systems;

2)Heating systems in buildings, including floor, siding and radiant heating systems;

3)Pure water supply system that can be used for direct drinking; 4)Central air conditioning system drainage;

5)Industrial piping systems for transporting or discharging chemical media.

Can Be Solve issues Of PPR Pipe!

- Corrosion: PPRPipe is highly resistant to corrosion, making it an ideal choice for clients who require reliable and durable piping solutions in harsh environments.

- Chemical Resistance: PPRPipe is resistant to a wide range of chemicals, including acids, alkalis, and organic solvents. This makes it an ideal choice for clients who handle hazardous substances.

- Heat Resistance: PPRPipe is highly resistant to heat, making it an excellent choice for clients who require piping solutions that can withstand high temperatures.

- Longevity: PPRPipe has a long service life, reducing the need for frequent replacements. This translates to significant cost savings for clients over time.

- Low Maintenance: PPRPipe requires minimal maintenance, allowing clients to focus on their core business activities.

- Energy Efficiency: PPRPipe has excellent insulation properties, reducing energy losses and subsequently reducing energy costs for clients.

- Easy Installation: PPRPipe is easy to install, saving clients time and money on installation costs.

- Environmental Sustainability: PPRPipe is made from environmentally friendly materials and is fully recyclable. This makes it an ideal choice for clients who are committed to reducing their environmental impact.

- Versatility: PPRPipe is suitable for a wide range of applications, including chemical transport, water supply, heating, and cooling systems. This versatility makes it an ideal choice for clients in a variety of industries.

- Compliance: PPRPipe meets all relevant industry standards and regulations, ensuring that clients remain compliant with applicable laws and regulations.

In summary, PPRPipe is a versatile, durable, and efficient piping solution that can address a variety of common challenges faced by clients across industries. Its resistance to corrosion, chemicals, and heat, as well as its longevity, low maintenance requirements, and environmental sustainability, have made it a highly sought-after choice for clients worldwide.

OEM & ODM Service

ODM (Original Design Manufacturing) and OEM (Original Equipment Manufacturing) are two approaches to manufacturing products. ODM involves designing and manufacturing products based on a customer’s specifications, while OEM involves manufacturing products according to a customer’s design and branding.

To serve customers with general ODM or OEM, you need to understand their specific requirements and work closely with them to ensure that the final product meets their needs. Some key steps for serving ODM or OEM customers include:

Understanding the customer's requirements:

Work with the customer to define their requirements for the product, including functionality, design, materials, and production volumes.

Designing the product:

Based on the customer’s requirements, design the product to meet their specifications, using the latest tools and technology to create accurate 3D models and prototypes.

Manufacturing the product:

Once the design has been approved by the customer, manufacture the product using high-quality materials and reliable production processes, ensuring that the product meets all relevant safety and quality standards.

Testing and inspection:

Before delivering the product to the customer, conduct rigorous testing and inspection to ensure that it meets all specifications and standards.

Delivering the product:

When the product is ready, deliver it to the customer on time and in good condition, providing any necessary documentation and support to ensure a smooth installation and operation.

Throughout the process, communication and collaboration with the customer are key to ensuring that the ODM or OEM product meets their needs and exceeds their expectations.

IFAN FAQ

PPR pipe is made of a type of random copolymer polypropylene that is a thermoplastic material commonly used in PPR Plumbing Fittings.

PPR pipe is highly durable, corrosion-resistant and can withstand high temperatures and pressure. It is also easy to install and has a longer lifespan compared to other types of pipes.

PPR pipe can be more expensive than other types of pipes and may not be readily available in certain regions. It is also not suitable for use in outdoor applications as it can become brittle when exposed to UV rays.

PPR pipe can be installed using a variety of techniques, including welding, fusion, and crimping. It is important to ensure that the installation is done by a professional to prevent leaks and ensure proper functioning.

PPR pipe can be recycled by melting and reforming the plastic into new products. However, the recycling process can be expensive and not widely available in certain regions.

The smooth handle of PP-R pipes is a distinguishing feature of a good PP-R pipe. The smooth handle and the soft surface are a sign of good quality. However, a poor-quality PP-R pipe is likely to have impurities in its composition. In addition, a good PP-R pipe should have a uniform wall thickness and no odor.

PPR pipes can withstand high temperatures up to 95°C, making them suitable for use in hot water supply systems. PPR pipes have a long lifespan of up to 50 years or more under varying and extreme environmental conditions, making them a cost-effective option in the long term.

The raw material of PPR is separated into 3 groups according to heat, pressure and durability for chemicals. These are Type-1(polypropylene homo polymer), Type-2(polypropylene block copolymer) and Type-3 (Polypropylene Random copolymer).

Most common PPR pipe applications include: Hot and cold potable water piping in residential, industrial, and public installations. Industrial piping for transferring water, sanitary liquids, liquid food products .

The answer is yes. Although PPR pipes and PVC pipes are made of different materials, they can be connected by special fittings. In fact, this connection method is very common, and in some specific engineering projects, they are often used at the same time.