Introduction to PPR Piping

ppr thermofusion machine, or Polypropylene Random Copolymer, has emerged as a leading choice for piping systems. Its lightweight nature makes it easy to handle. The resistance to corrosion enhances its durability. These characteristics make PPR suitable for various applications, including residential and industrial use. Technological innovations have accelerated its adoption, particularly in hot and cold water systems.

The Role of Thermofusion

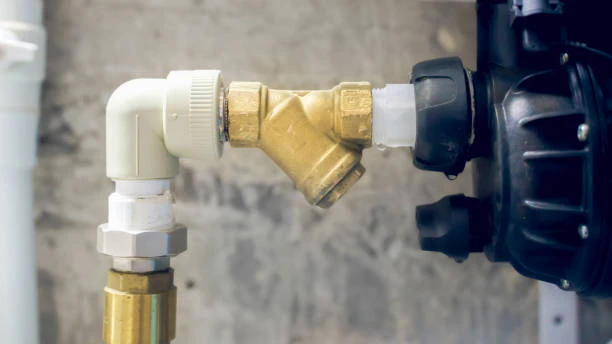

Thermofusion is a key process in PPR piping installation. This method joins pipes and fittings by heating them to a specific temperature. Once heated, they fuse together, creating a strong bond. This technique eliminates the need for additional adhesives or sealants. It ensures a leak-free connection, which is crucial for long-term performance. The use of a PPR thermofusion machine simplifies this process significantly.

Advances in PPR Thermofusion Machines

Recent innovations in PPR thermofusion machines have improved efficiency. Modern machines come with digital temperature controls. These controls ensure precise heating, enhancing the quality of the weld. Some machines now feature automatic shut-off functions. This reduces the risk of overheating and damage. Additionally, advancements in portability allow for easier use in various locations.

Smart Technology Integration

Smart technology is transforming PPR thermofusion machines. Many new models include IoT connectivity features. This allows users to monitor and control the machine remotely. Real-time data collection optimizes the welding process. Users can receive alerts for maintenance needs, increasing machine lifespan. Such features enhance the overall user experience and operational efficiency.

Enhanced Safety Features

Safety remains a top priority in piping technology. Recent PPR thermofusion machines include advanced safety mechanisms. Many models feature automatic pressure release valves. These valves prevent overheating and potential accidents. Additionally, enhanced insulation protects users from burns during operation. Training protocols have also improved, ensuring operators understand safety practices.

Environmental Considerations

Environmental sustainability is crucial in today’s market. PPR is recyclable, which appeals to eco-conscious consumers. Innovations in thermofusion technology also support this trend. These machines consume less energy than traditional methods. This reduction in energy use contributes to lower carbon footprints. Manufacturers are focusing on producing machines that align with green practices.

Cost-effectiveness of PPR Systems

Cost-effectiveness remains a significant advantage of PPR piping. The initial investment in PPR thermofusion machines can be offset by long-term savings. PPR systems require less maintenance compared to metal pipes. Their longevity reduces replacement costs over time. Moreover, energy savings from efficient thermal insulation contribute to overall cost benefits.

Conclusion: The Future of PPR Technology

The future of PPR piping technology looks promising. Continuous advancements in thermofusion machines enhance efficiency and safety. Smart features will likely become standard in upcoming models. As industries prioritize sustainability, PPR’s popularity will grow. The combination of durability, cost-effectiveness, and innovation makes PPR piping a top choice for the future.

IFAN Products international standards

IFAN products strictly adhere to a comprehensive range of international standards, encompassing ISO 15874, EN 15874, ASTM F2389, DIN 8077/8078, GB/T 18742, NBR 15884, ISO 15494, EN ISO 15494, GB/T 19472, NBR 15494, ASTM 2846 (501), DIN 8079/8080 (502), ASTM F441/F441M SCH80 (503), DIN (504), DIN (505), GB/T 18993, AS/NZS 1477, CSA B137.6, NSF/ANSI 14, TIS 17-2532/1131-2535, BS 3505, BS 4346 (801), ASTM D1785 SCH40 (802), ASTM D1785 SCH80 (803), DIN (804), GB (805), GB (806), GB(901), DWV(902), ASTM D2665 (903), along with ASTM D2241, D2665, D2729, and F441/F441M series, ISO 1452, EN ISO 1452, DIN 8061/8062, GB/T 10002, AS/NZS 1477, JIS K6741, CSA B137.3, and other national and industry norms.

Connect

IFAN is a Chinese manufacturer of plastic pipes, fittings and valves with 30 years of experience. If you are interest in IFAN copper fittings, copper valves, plastic pipes and fittings, please contact us. IFAN offers you a variety of standard pipes to meet your specific needs. Click below to learn more about IFAN’s wide range of affordable and cost-effective valve products and piping system related products.

We will reply your email or fax within 24 hours.

You can call us at any time if there is any question on our production.

For more information,pls visit our webside https://waterpipefitting.com/

Pls Mailto: [email protected]

Whatsapp: +86 15088288323

Recent Comments